-

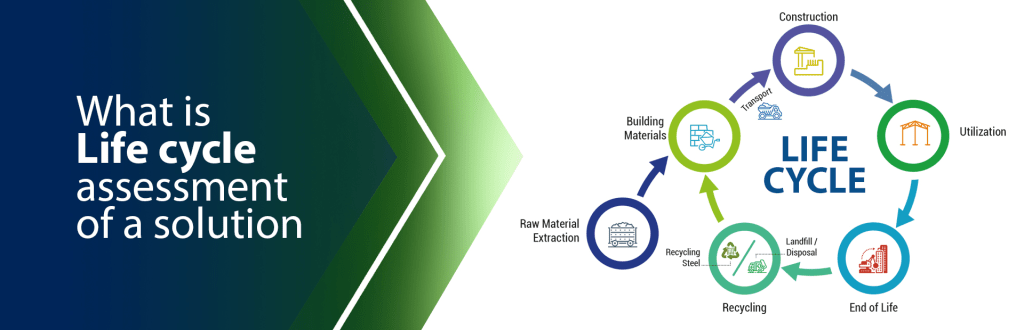

WHAT IS THE LIFE CYCLE ASSESSMENT OF A SOLUTION?

Life Cycle Assessment (LCA), also called life cycle analysis, is a holistic way to measure the impact of a product, service, or process on the environment during different life stages/cycles. Different parts of the product’s or process’ life cycle can affect the environment in many ways.

LCA studies are guided by ISO 14040 & 44 and involve a complete list of inventory flow in each stage of the product’s life cycle, including materials, energy, emission, waste generated, etc. LCA can be conducted for different scopes, which are:

- Gate to gate – Focuses only on the manufacturing process

- Cradle to gate – It focuses on the extraction of raw materials from nature until they reach the manufacturing unit.

- Cradle to grave – From the extraction of raw materials to the product disposal

Conducting a Life Cycle Assessment of a product has many benefits. It helps improve product development in efficient policymaking.

Steps of life cycle assessment

LCA is a standardised method that makes the assessment transparent and reliable, and as per the ISO standards, there are four main steps of LCA.

- Defining the goal

- Analysis of the inventory

- Assessing the impact

- Interpreting the findings/assessment

Life Cycle Assessment of HabiNest, a prefab construction solution offered by Tata Steel Nest-In

HabiNest is a Light Gauge Steel Frame (LGSF) solution ideal for building residential buildings and industrial amenities. These buildings are constructed in one-third the time it takes to build a structure of the same size using conventional methods.

Recently a LCA study was conducted on a HabiNest structure of classroom building. The total built area of the construction was approximately 2400 Sq. Ft which was compared with a conventional structure of a similar size.

The total material used in HabiNest was about 192 tons, while for a traditional structure of similar size, it was 547 tons.

-

THE HISTORY OF MODULAR BUILDINGS & MODULAR CONSTRUCTION

Over the years, the popularity of modular buildings has grown tremendously. While this unique building and construction method may seem to be new, the truth is it has been around for nearly two centuries. The first documented modular or prefabricated home was created by a London-based architect named John Manning in 1837.

Manning built a prefabricated house and shipped the units for easy assembly on-site. The home’s appearance and unique design attracted the locals’ interest. Modular construction soon gained popularity.

By 1853, hundreds of such modular homes were shipped to Australia, and these buildings were sighted all over the globe. During the California Gold Rush, which started in 1848 and ended in 1855, California saw a massive surge of immigrants; about 300,000 people from all over the world came to the city, and modular building became an effective solution to provide them a place to stay. Modular building construction made it easy for the Americans to assemble the components upon their arrival in America and complete the house in a quick span of time.

-

A COMPLETE GUIDE TO PREFABRICATED VILLA & IT’S CONSTRUCTION

Many dream of owning a villa. With the advent of modular or prefabricated construction technology, today, building a villa is easier and faster.

As people are growing more aware of the environmental concerns of traditional construction methods, many aspiring homeowners are choosing prefabricated homes. If you are unsure what a prefabricated villa is or how this construction technology works, here is a complete guide by Nest-In – a prefabricated construction solution from the house of Tata Steel.

What is prefabricated construction?

Prefabricated construction is an innovative technology where different parts or modules of the home or building are manufactured off-site in a factory. These parts are then transported to the actual location for final installation, assembly, and finishing.

-

Hello World!

Welcome to WordPress! This is your first post. Edit or delete it to take the first step in your blogging journey.

-

Subscribe

Subscribed

Already have a WordPress.com account? Log in now.